|

Guest Contributor: Carol Phillips, Sales & Marketing Koetter Woodworking With the variety of paint grade moulding options available in the market, making the right choice isn't always easy. If you ask trim carpenters their preferred species to work with, the large majority will tell you "Poplar". Sometimes referred to as the "Tulip Tree", Poplar can grow up to 160 ft. tall in the virgin forests of the Appalachian Mountains. Often, the tree does not develop limbs until it reaches 80 - 100 ft in height, No limbs means fewer knots and longer, straighter trunks, making Poplar the #1 choice for interior millwork & doors! Features & Benefits

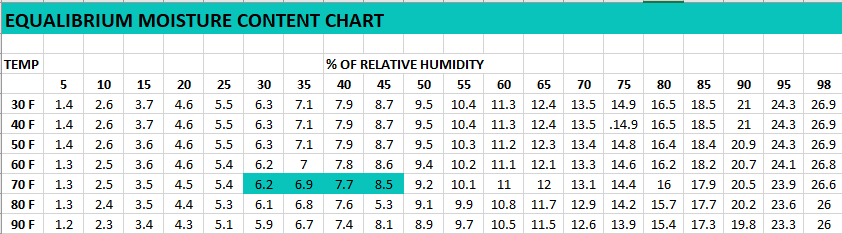

As temperatures and humidity levels rise, it is more important then ever to ensure all wood products are properly handled in the field, including acclimation, finishing and installation. Architectural millwork, is indeed, much like fine furniture. If the indoor relative humidity is not controlled on the job site there is a chance that the owner will encounter wood movement throughout the life cycle of the project. Here are several key factors to take into consideration for the successful installation and finishing of a millwork trim and door package:

Additional Resources To Help You Plan Accordingly

|

AuthorThe U.S.Architectural Millwork Blog is written by company thought leaders who have a strong pulse on the industry. They're expressive, skillful, and passionate about their jobs and our customers. Passion causes you to open your mouth when sometimes a whisper will do. ArchivesCategories |

RSS Feed

RSS Feed